ON-LINE MANUAL

Vibrator

Selection

In this section

you will find some suggestions on how to select vibrators, but selection

of the optimal vibrator cannot be done soely by using a calculator, some

graphs and tables. Every single application is to be treated in a different

way. Very often the free vibration is hindered by structural reinforcements,

stiffeners, or other impediments. The following tables may give you an

approximate idea to come close to the optimum, but in the end the final

adjustment has to be done by varying the air pressure and tuning in to

the object's natural frequency or a frequency that provides good working

conditions.

There are many

applications where three or more types of vibrators will do the job. In

these cases the decision on which vibrator to use needs to be made according

to noise and cost, both initial and long-term.

Generally speaking

there are 7 factors to be taken into consideration :

- air consumption

- noise

- space of the unit

/ mounting area

- frequency required

- amplitude / vibrating

energy

- cost / maintenance

cost

- air supply / lubrication

necessary

You will find different

types of vibrator listed in the following tables, listed according to their

force and amplitude. Other factors which are important are cost, noise

and air consumption. For example, it might sometimes be important to use

a Golden Turbine Vibrator, which is less noisy and consumes less than half

the air that a ball vibrator with similar characteristics. For other applications

there are no noise restrictions and a ball vibrator will be sufficient

and save money as well.

How to proceed

:

- Select all the

possible vibrator types and models according to the force needed in the

following tables.

- If silent operation

is required, then do not use noisy types.

- If oil-free running

is required, then do not use T-, DAR-, and FP-vibrators.

- If low air consumption

is required, do not use Ball- and Roller-Vibrators (K-, R- and DAR-vibrators).

For air consumption data please refer to Section 10--Technical Data.

- Check for the mounting

space needed.

- Compare the costs.

Take into consideration that one single GT-vibrator may do the job of two

ball vibrators and that it might be less expensive in the long run.

Bins And Hoppers

Formula

The most important

factor in selecting the optimal vibrator model is the weight of the good

that has to be vibrated. Where bins and hoppers are concerned, only the

material in the sloped part of the bin or hopper is of interest.

Weight of the

content :

W(cont) = Volume

x Volume Weight of the Material

(b1 x L1 + b2 x L2)

W(cont) = ------------------------

x h x VW for square bins

2

(r12 x p + r22 x p)

W(cont) = ------------------------

x h x VW for conical bins

2

Vibrator

table

Very often it is

better to run two smaller vibrators instead of a large one. The units should

be placed opposite each other on the bin or hopper so the structure is

not stressed toomuch at one single point.

| . |

Materials

|

Weight

of

the

content

in

lbs |

dry/loose

grain, corn,

coffee

dry powders,

flours

|

humid/wet/bulky

cement, concrete,

sugar

salt, chemicals

|

| . |

Ball

Vibrator

K-Type

|

Roller

Vibrator

R-Type |

Golden

Turbine

GT-Type |

(Ball)

Roller

Vibrator

R-Type |

DAR

Vibrator |

Golden

Turbine

GT-Type |

| . |

noisy

|

noisy

|

silent

|

noisy

|

noisy

|

silent

|

| 100 |

K-8

|

. |

GT-8

|

K-10

|

. |

GT-8

|

| 200 |

K-8

|

. |

GT-8

|

K-13

|

. |

GT-8

|

| 400 |

K-10

|

. |

GT-8

|

K-16

|

. |

GT-8

|

| 600 |

K-13

|

. |

GT-10

|

K-20

|

. |

GT-8

|

| 1000 |

K-16

|

. |

GT-13

|

R-50

|

. |

GT-8

|

| 1600 |

K-20

|

R-50

|

GT-13

|

R-50

|

DAR-2

|

GT-10

|

| 2,000 |

K-25

|

R-50

|

GT-16

|

R-50

|

DAR-3

|

GT-16

|

| 3,000 |

K-30

|

R-50

|

GT-16

|

R-65

|

DAR-4

|

GT-20

|

| 4,000 |

K-36

|

R-65

|

GT-20

|

R-80

|

DAR-4

|

GT-25

|

| 6,000 |

K-36

|

R-65

|

GT-25

|

R-100

|

DAR-5

|

GT-36

|

| 10,000 |

. |

R-80

|

GT-30

|

R-120

|

DAR-6

|

GT-40

|

| 15,000 |

. |

R-100

|

GT-40

|

. |

DAR-7

|

GT-48

|

| 20,000 |

. |

R-100

|

GT-48

|

. |

DAR-7

|

GT-48-S

|

Selection

table for bins and hoppers

Chutes And

Screens

To select the correct

vibrator, first determine the weight of the material and the volume to

be moved. For smaller chutes and screens, up to a total of about 120 kg,

piston vibrators can be used but for larger chutes and screens, rotary

vibrators, especially turbines, are a better choice.

Where two vibrators

have to be used make sure both are fixed to the same stiffening iron so

they will immediately run in resonance and amplify their forces.

Formula

Total weight to

be vibrated :

W(vib) = Weight

of chute or screen (moving part) + weight of the material inside

Vibrator

table

Total

weight

in lbs |

Ball

vibrator

K-type

noisy

SA/HF

|

Roller

vibrator

R-type

noisy

MA/HF

|

Roller

vibrator

DAR-type

noisy

HA/LF

|

Turbine

vibrator

GT-type

silent

LA/MF

|

Piston

vibrator

FP-type

silent

1/LF

|

|

10

|

. |

. |

. |

. |

FP-12

|

|

20

|

. |

. |

. |

. |

FP-18

|

|

30

|

. |

. |

. |

. |

FP-18

|

|

40

|

K-8

|

. |

. |

. |

FP-25

|

|

60

|

K-8

|

. |

. |

. |

FP-25

|

|

80

|

K-10

|

. |

. |

. |

FP-25

|

|

100

|

K-13

|

. |

. |

. |

FP-35

|

|

150

|

K-16

|

. |

. |

. |

FP-35

|

|

200

|

K-20

|

. |

. |

. |

2xFP-35

|

|

300

|

K-25

|

R-50

|

DAR-2

|

GT-16

|

. |

|

400

|

K-30 |

R-50

|

DAR-3

|

GT-16

|

. |

|

600

|

K-36

|

R-65

|

DAR-4

|

GT-25

|

. |

|

800

|

2x K-36

|

R-80

|

DAR-5

|

GT-36

|

. |

|

1,000

|

. |

R-100

|

DAR-6

|

GT-36-S

|

. |

|

1,500

|

. |

R-120

|

DAR-7

|

GT-48

|

. |

|

2,000

|

. |

R-120

|

DAR-7

|

GT-48-S

|

. |

|

4,000

|

. |

2xR-120

|

2xDAR-7

|

2xGT-48-S

|

. |

Selection

table for chutes and screens

The FP-vibrators

are available as S(mall), M(edium) and L(arge)

amplitude types

| SA = small

amplitude |

LF = low frequency |

| MA = medium

amplitude |

MF = medium

frequency |

| HA = high amplitude |

HF = high frequency |

Molding Forms

For Concrete and Iron Cast Applications

The important factors

in selecting a vibrator for concrete molds are the mold weight and the

condition of hte concrete, either dry, medium, or wet.

NOTE : Whatever

vibrator you choose from the table, you will always have to perform practical

tests to determine its best working conditions. Especially for concrete,

the time of vibration is of significant importance to insure that the concrete

is vibrated throughout. The table only provides a rough estimate.

|

Condition

|

Weight

of

filled mold

in lbs |

WET |

MEDIUM |

DRY |

|

40

|

R-50

DAR-2

GT-10-S

|

R-50

DAR-3

GT-10-S

|

R-65

DAR-4

GT-10-S

|

|

100

|

R-50

DAR-2

GT-10-S

|

R-65

DAR-3

GT-16-S

|

R-65

DAR-4

GT-16-S

|

|

200

|

R-65

DAR-5

GT-16-S

|

R-65

DAR-5

GT-16-S

|

R-80

DAR-6

GT-25-S

|

|

400

|

R-65

DAR-5

GT-25-S

|

R-80

DAR-6

GT-25-S

|

R-100

DAR-6

GT-36-S

|

|

1,000

|

R-80

DAR-6

GT-36-S

|

R-100

DAR-6

GT-48-S

|

R-120

DAR-7

2x GT-36-S

|

|

1,500

|

R-120

DAR-6

GT-48-S

|

R-120

DAR-7

2x GT-36-S

|

2x R-120

2x DAR-6

2x GT-48-S

|

|

2,000

|

2x R-120

DAR-7

|

2x R-120

2x DAR-6

|

2x DAR-7

|

Selection

table for concrete molds

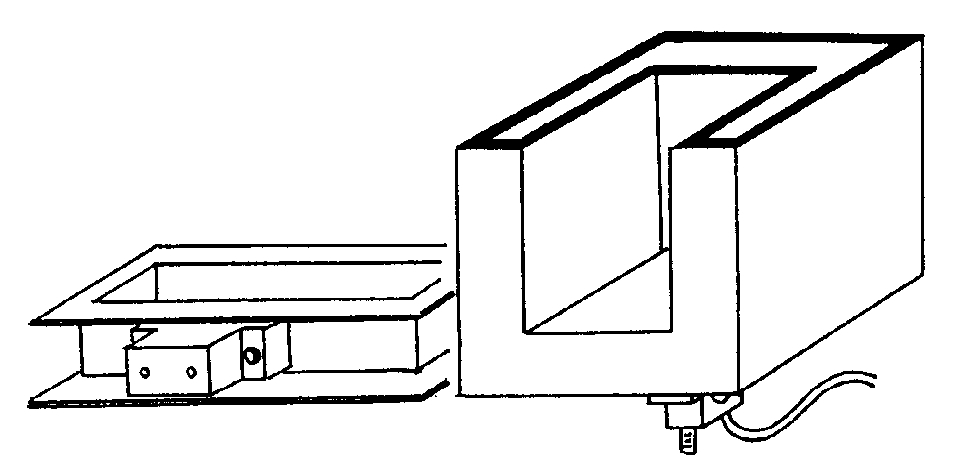

Fixation

of the Vibrators depending on molding form

When more than

10 cm (4 inches) of concrete are to be compacted, DAR-vibrators (above,

on the right) are recommended. The DAR-vibrators produce very large amplitudes

which penetrate deeply into the concrete material.

For flat molding

forms (above, on the left), DAR-vibrators should be used if the total width

is more than 20 cm (8 inches) or 40 cm (16 inches) if two vibrators are

used. If the width is less than 20cm, roller R-series or turbine GT-vibrators

will produce good results.

To get a very

compact and bubblefree surface, a GT-vibrator should be run for about ten

seconds. Due to its higher frequency, it compacts sand material closely

around gravel stones.

4.5. Foundry Molding

Forms

To determine the

correct vibrator to separate the silica sand of molding forms use the DRY

column on the table. The use of GT-turbines is recommended since they can

be operated without lubrication and their ball bearings are shielded so

the silica sand dust can not harm the bearings. The vibrator should always

be supplied with about 0.5 bar in standby operation so that no silica sand

enters the exhaust port during the filling of the mold. Higher pressure

is necessary to start the vibrator.

NEXT TO MOUNTING PART 1